Case Study: Dust Hazard Analysis and Combustible Dust Explosion Mitigation in Oilseed Processing

Combustible dust poses a significant risk across various industries, and oilseed processing is no exception.

With over 100 Dust Hazard Analyses (DHAs) conducted across North America since 2016, ADF has established itself as a leader in identifying and mitigating the risks associated with combustible dust in the oilseed processing industry.

This case study highlights ADF’s expertise in conducting DHAs, particularly in soybean oil crush plants, and the tailored solutions provided to address the unique challenges within this sector.

Industry Overview: Oilseed Processing

Oilseed processing, specifically soybean processing, involves several critical steps that generate combustible dust. The risk is exacerbated in facilities using either hexane extraction or mechanical extraction technologies.

ADF’s extensive experience in this sector, combined with its active involvement in the American Oilseed Chemist Society (AOCS) since 2011, has positioned itself as a trusted partner in combustible dust mitigation.

Industry Challenges

Aging Facilities with Outdated Equipment

Many soybean preparation plants are decades old, and their dust control systems reflect the engineering standards of the past.

These facilities often feature large aspiration collectors that interconnect multiple flakers, crackers, screeners, and aspirators through extensive ductwork. The lack of proper isolation between these components presents a significant risk of propagating dust explosions throughout the plant.

Combustion Protection for Existing Mills

Hammermills, a critical component in soybean processing, are particularly vulnerable to dust explosions.

NFPA 61 provides clear guidelines for explosion protection in these mills, but older facilities often struggle to implement these protections due to space constraints.

The challenge lies in retrofitting these mills with modern explosion protection equipment without disrupting operations or requiring extensive modifications to the existing infrastructure.

Inadequate Combustibility Data

The data available for the combustibility of soybean dust and meal dust is often outdated.

Many facilities rely on old literature, which may not accurately represent the current operational conditions. This issue is even more pronounced for other oilseeds like cottonseed and sunflower, where combustibility data is scarce or nonexistent.

Tailored Solutions by ADF

Upgrading Dust Collectors for Explosion Protection

ADF begins by evaluating the existing dust collectors in aging facilities to determine their suitability for supporting explosion protection upgrades.

If the collectors are inadequate, ADF designs reinforcements to ensure they meet modern safety standards. This proactive approach minimizes the risk of dust explosions while extending the life of existing equipment.

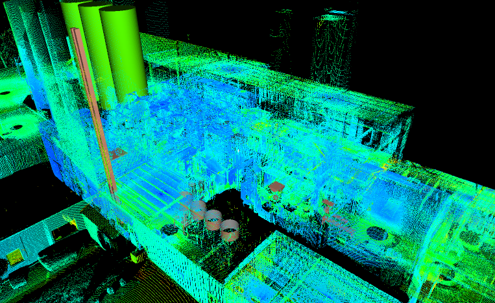

Laser Scanning for Precise Explosion Mitigation

For facilities with tight spaces, ADF employs laser scanning technology to create detailed maps of the hammermills and surrounding areas.

This precise data allows ADF to identify optimal locations for installing explosion mitigation equipment, even in challenging environments.

The use of laser scanning ensures that the solutions provided are both effective and minimally invasive.

Customized Combustibility Testing

Recognizing that each soybean processing plant operates under unique conditions, ADF advocates for customized combustibility testing of soybean meal dust.

We partner with reputable testing laboratories to facilitate this process, ensuring that the data obtained is representative of the specific operational environment.

This tailored approach allows for more accurate risk assessments and the implementation of more effective mitigation strategies.

In Summary

ADF Engineering’s expertise in conducting Dust Hazard Analyses and mitigating combustible dust risks in the oilseed processing industry is unmatched.

By addressing the unique challenges posed by aging facilities, space constraints, and outdated combustibility data, ADF has consistently delivered solutions that enhance safety and operational efficiency.

For companies in the oilseed processing sector, partnering with ADF ensures that combustible dust hazards are thoroughly assessed and effectively managed, safeguarding both employees and assets.

If you need assistance with your DHA analysis, please contact us.